Maximising Efficiency with Bonded Warehouses

Introduction to the Concept of Bonded Warehousing

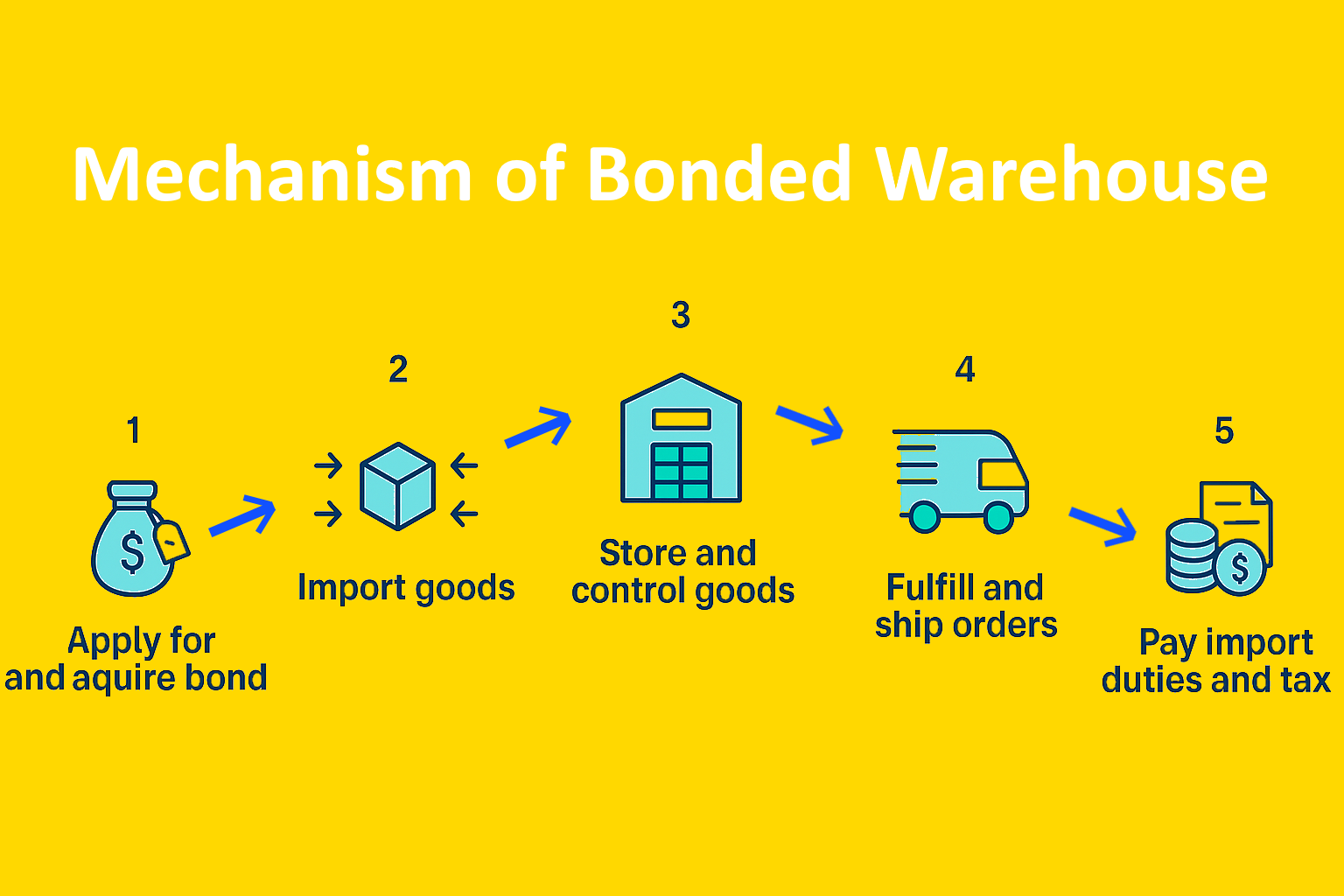

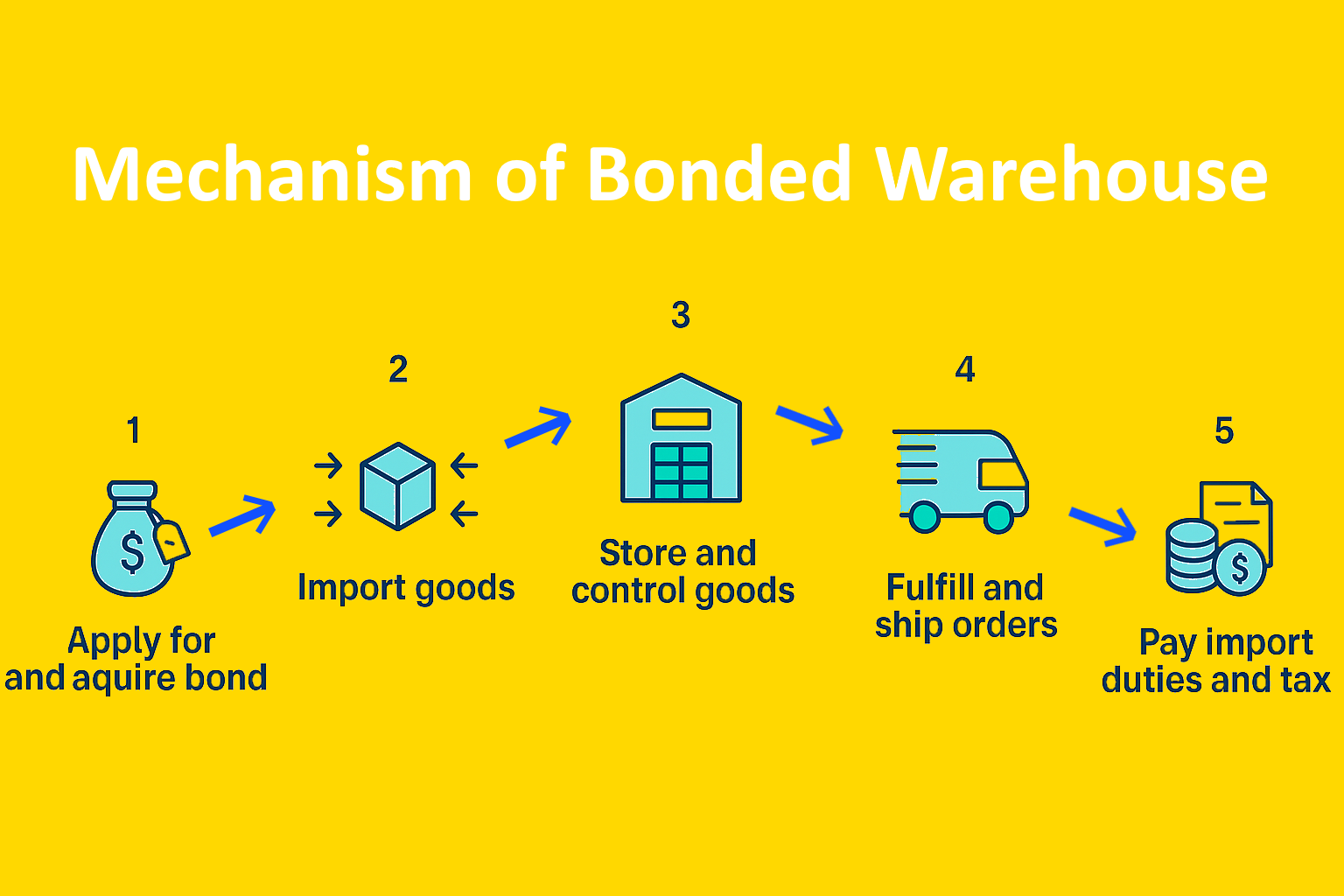

A bonded warehouse plays a crucial role in modern logistics, especially for businesses involved in large-scale storage and international trade. These warehouses allow businesses to store imported goods without immediately paying duties, offering significant cost-saving opportunities. By deferring tax payments until products are ready for distribution, companies can streamline operations, manage inventory more effectively, and enhance overall supply chain efficiency.

Additionally, bonded warehouses ensure that companies can meet market demands more efficiently by having their products ready for dispatch without unnecessary delays. Businesses operating in highly regulated industries, such as food packaging, particularly benefit from the ability to store goods in a compliant and controlled environment.

Streamlining Operations With Bonded Warehouses

Efficiency is at the core of bonded warehouse operations. These facilities help businesses mitigate customs delays, ensure compliance with international trade regulations, and facilitate smoother shipping processes. Companies in industries such as food packaging benefit immensely from bonded storage solutions, as they enable secure storage and systematic distribution of goods without unnecessary delays at customs checkpoints.

Bonded warehousing also allows businesses to consolidate shipments, reducing transportation costs and enhancing overall distribution efficiency. By optimising supply chain logistics, companies can respond quickly to fluctuations in demand while maintaining high service levels.

Cost Savings In Bonded Warehousing

One of the most attractive advantages of utilising a bonded warehouse is the potential for cost savings. Businesses can defer duty payments, allowing them to allocate funds elsewhere and improve cash flow. Additionally, bonded warehousing reduces long-term storage costs by eliminating the need for multiple handling points. For companies in the food packaging industry, this means lower overhead expenses and enhanced financial flexibility.

By leveraging bonded warehousing, businesses can also reduce inventory holding costs and avoid potential fines or penalties associated with customs non-compliance. Furthermore, streamlined logistics can result in fewer product losses, leading to better profit margins.

Read more about contract packing for food.

Security And Risk Management In Bonded Warehouses

Security is a top priority in bonded warehouse operations. Advanced security measures, including CCTV surveillance, restricted access, and strict compliance with customs regulations, help prevent theft, damage, and financial penalties. Businesses storing valuable or sensitive products, such as perishable food items, benefit from the stringent security protocols in place with bonded warehouses.

Regular audits and inspections ensure that compliance standards are upheld, giving businesses peace of mind that their products are safe and accounted for. Moreover, risk management strategies such as insurance and real-time monitoring systems further enhance the security of bonded warehouse operations.

Technological Advancements In Bonded Warehousing

Technology is transforming the bonded warehouse landscape, making operations more efficient and secure. Automated inventory tracking systems, AI-powered logistics management, and real-time monitoring ensure seamless coordination between storage and distribution. These innovations are particularly beneficial in the packaging and logistics sectors, where precision and speed are critical.

Choosing The Right Bonded Warehouse For Your Business

Selecting the right bonded warehouse is essential for optimising business operations. Key considerations include location, storage capacity, compliance with industry regulations, and the range of services offered. Companies should assess potential warehouses based on their ability to accommodate specific storage needs, particularly if they deal with perishable or temperature-sensitive products.

Additional factors such as proximity to transport hubs, reputation for compliance, and customer service capabilities can further influence a business’s choice in selecting a bonded warehouse.

Future Trends In Bonded Warehousing

The future of bonded warehouse operations is being shaped by advancements in technology and sustainability. Green warehousing practices, such as energy-efficient storage facilities and eco-friendly packaging solutions, are becoming more prevalent. Additionally, blockchain technology is being explored to enhance inventory tracking and improve transparency across the supply chain.

With the rise of e-commerce and increasing global trade complexities, bonded warehouses will likely incorporate further automation and AI-driven logistics solutions to maximise efficiency and meet growing demand.

Best Practices For Managing Bonded Warehouses

To ensure the successful management of a bonded warehouse, businesses should adopt best practices such as:

-

Maintaining accurate and up-to-date inventory records.

-

Investing in staff training to ensure regulatory compliance.

-

Leveraging automation for improved efficiency.

-

Conducting regular audits to mitigate risks and maintain operational integrity.

-

Staying updated on international trade laws and adjusting operations accordingly.

Unlock The Potential Of Bonded Warehousing For Your Business

A bonded warehouse offers businesses an opportunity to enhance efficiency, reduce costs, and secure their operations. Whether you are in the food packaging industry or another sector requiring large-scale storage and international distribution, leveraging bonded warehousing solutions can provide long-term benefits. Explore bonded warehousing today and unlock its full potential for your business.