A Guide to Flow Wrapping (Horizontal Bagging)

Learn about flow wrapping (horizontal bagging): the method of moving raw material horizontally along a machine & wrapping it in film & sealing at either end.

Read More

The innovative flow wrapping machine, which is also called a horizontal form fill seal machine, is chosen for a wide variety of solid products and materials. These can include food (particularly biscuits, snack bars, cakes and chocolate bars) as well as non-food items, such as leaflets, scratch cards, tissues, toys, accessories, electrical items, and any products that need to be bundled together. If this sounds right for you, read on to discover how flow wrapping will benefit your product range.

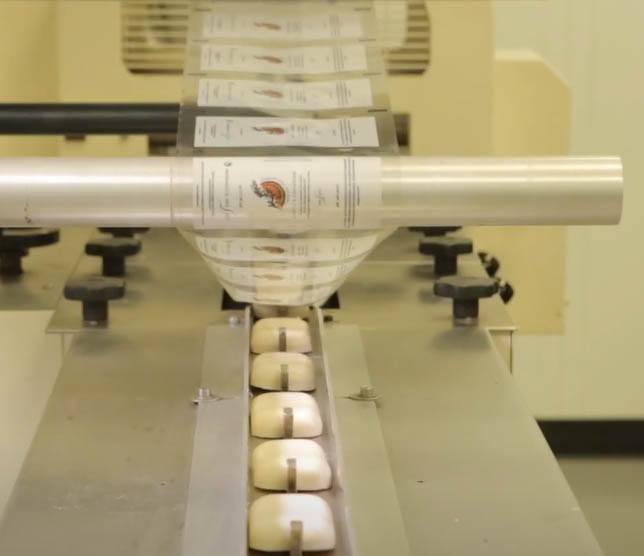

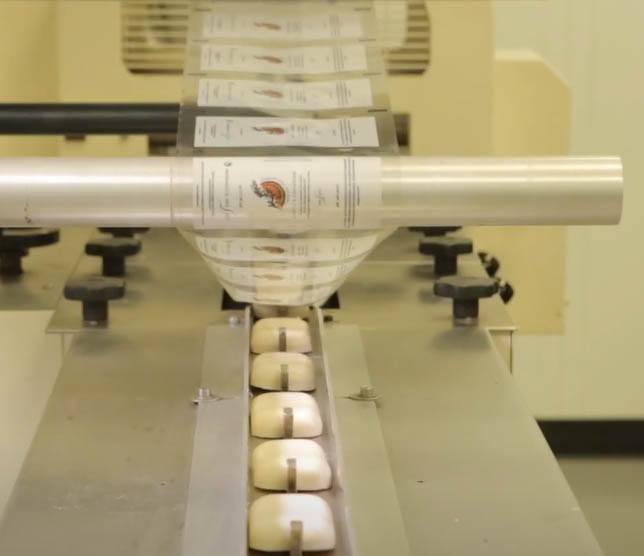

The flow wrapping method sees products pushed through a conveyor belt and wrapped in plastic film, which is then sealed at both ends. The result is a highly secure and cost-effective form of packaging that can be carried out at high speeds, with up to 70 units sealed every minute. This fast and reliable system makes flow wrapping a very popular choice that suits requirements, timeframes and budgets alike.

Perhaps the most appealing factor of flow wrapping is that your products are sealed in a strong layer of plastic film. Aside from preventing products from breaking free of their packaging, this also keeps out dust, moisture and UV rays. Your products are even protected against direct handling, as the film keeps everything in pristine condition throughout the storage and logistics stages.

Many of our customers choose flow wrapping because the packaging is particularly lightweight. This means that individual units, and more importantly bundled batches, are lighter than they would be compared to many other types of packaging. As a result, shipping costs are lower and the carbon footprint during transit is reduced, which benefits both your profit margins and the environment.

Another benefit of flow wrapping is brand visibility, as WePack can also provide printing services that make your artwork stand out whilst keeping barcodes, tracking numbers and other key information easily accessible. If you’re interested in this service, get in touch with our team to explore your options.

Whilst the team here at WePack is proud to work with businesses that are only just entering the world of packaged products, we also deliver our services to brands that require very large product runs. Flow wrapping is an excellent option for large-scale requirements, as we typically handle projects of anywhere between 2,500 and 500,000 bags, plus we can easily accommodate much bigger requirements.

Fascinated by the applications of flow wrapping? We know how you feel! That’s why we’ve put together this guide to flow wrapping and horizontal bagging, which covers everything from what the bag will look like to the expected costs. This guide also explains the difference between flow wrapping and shrink wrapping, which will help you to make an informed decision when choosing the right kind of packaging service for your product lines.

If you’re interested in our flow wrapping service, our packaging specialists are ready to discuss your requirements and recommend a fully tailored solution. To find out more, get in touch on 0115 852 9000 or fill in our contact form.